Electric planetary geardrive for Warbirds of 25kg class

The E-SPX is our latest development: A electric planetary geardrive. New? No, an old hat, existing since years! Well, nearly right, but… Stay excited and continue reading below!

Here is our short intro-video. Please click this text. (Sorry, german only)

Another one, special thanks to Wadl and Steffi!

Technical data of E-SPX

General data:

| Gear ratio: | 1:3 |

| Propellerspeed: | 3000 rpm |

| Motorspeed: | 9000 rpm |

| Propellersize: | 34×40″ five blade |

| Static thrust: | 25 kp |

Power data:

| max. batt voltage: | 52 V |

| max. current: | 260 A |

| max. electr. power: | 13,5 kW |

| max. mech. power: | 12 kW |

| approx. flight time: | 8-9 min |

Weights (appr):

| Torqstar 7040/10: | 1600 g |

| planetary gear drive: | 1140 g |

| battery 14S 16Ah: | 4500 g |

| controller: | 300 g |

| power plant mount (plywood 3D structure): | 700 g |

| complete powerplant: | 8240 g |

Note: Weights may change by technical development.

Video of maiden flight

Despite long research, we have not found a planetary gear drive in this performance class that can turn such large multi-blade propellers as a warbird of the 25kg class requires.

Therefore, it was clear: We want to close this gap! We develop a high-tech drive that meets all requirements!

We tested the drive in our veteran and battle-tested Seafury 4.5:1 with 2.65m wingspan and flew it very successfully.

And due to its compactness, it also fits under the cowling of warbirds, which were originally driven by an in-line engine. This means that every pilot who wants to give his warbird a true-to-original propeller has all the possibilities with this transmission bolide.

The Background

A few years ago, we started to develop the SP-250-X planetary gear drive with Moki S250. In 2017, this powerplant had its debut at the Warbirdmeeting Oberhausen and was perfectly presented by our chief pilot Stefan Jahnke.

Installed in our Seafury with faithfully large 5-blade propeller, this presentation was honored with the trophy “Best of Show”. It can probably be said that the drive has raised the neck hairs of most pilots on the field!

After several SP-250-X engines were sold and they made their new owners happy, it turned out that the quality of the Moki engines available afterwards no longer met our expectations.

The planetary gearboxes worked perfectly, but the engines have become known to have had a fundamental problem with piston breaks.

We decided very quickly that we would not sell drives with these motors, as all liability claims of the customers had to be settled directly by us. For the gearbox mounting, we have rebuilt the engine and equipped it with proven tuning parts. Of course, the original engine manufacturer Moki/Airworld was no longer in the obligation.

The Solution

Alternatively, talks with Fiala/Valach took place, as a new comparable 5-cylinder with 250cm³ has just come onto the market. On closer inspection, it turned out that the installation of the gearbox would have resulted in an almost complete new development of the gearbox. The engine is significantly different in the front area than the Moki engines.

In addition, it was uncertain whether similar service problems as Moki/Airworld would occur. In fact, there were various technical difficulties and faltering delivery capability with the VM R5-250 at the beginning, which is why we stopped doing so.

We have not seen many other alternatives on the market.

Therefore, the following thought came up:

Why not an equal drive in an electric version? A drive unit that has the potential to replace the SP-250-X? To chase a 25kg warbird through the air with at least the same power as the Moki S250 can?

At the same time, however, large propellers were to be turned again true to the original. In the American warbirds such as Corsair, Bearcat, Thunderbolt or even the Seafury, the diameters of the 4- and 5-blade propellers had about 1/3 of the wingspan. The very large propellers gave the aircraft this brute flight performance and the equally gigantic appearance in the air.

Of course, others had this thought before:

There are some very different gear drives of the 7kW+ class: In large sailors planetary gearboxes are used, there are 1-stage open gear drives or even timing belt drives etc.

But what we imagined from a machine designer’s point of view was nowhere to be found:

A closed and compact planetary gear drive, which has a correspondingly stocky bearing to be able to mount even a very large rigid propeller with correspondingly large gyro forces and massive spinners cleanly.

With the available planetary gear drives, on the one hand the bearing was only sufficient for folding propellers, on the other hand the performance range was not large enough.

We do not want to go into the technical shortcomings of the open gearbox types in more detail here.

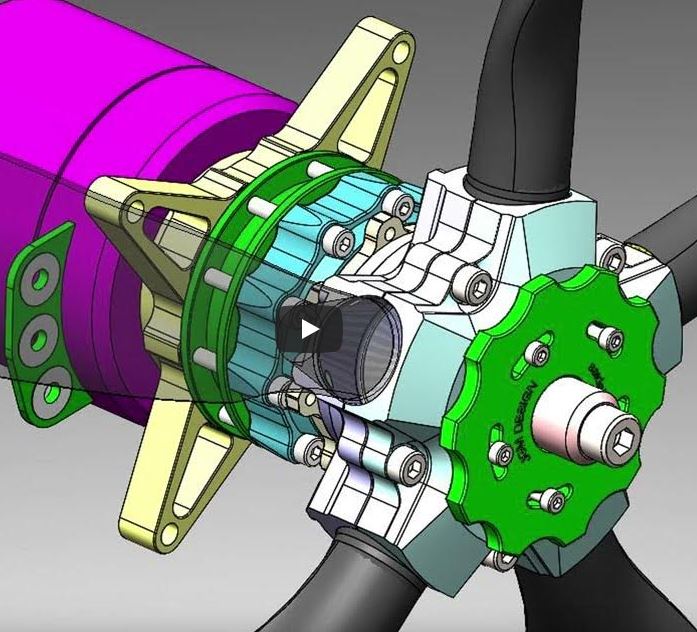

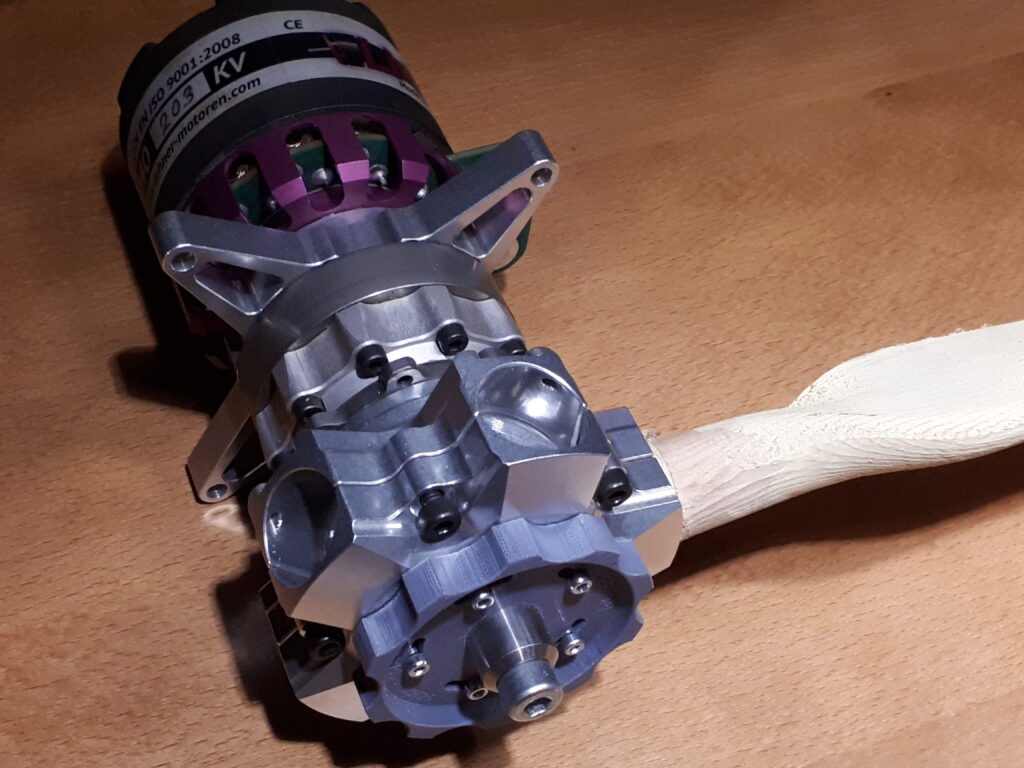

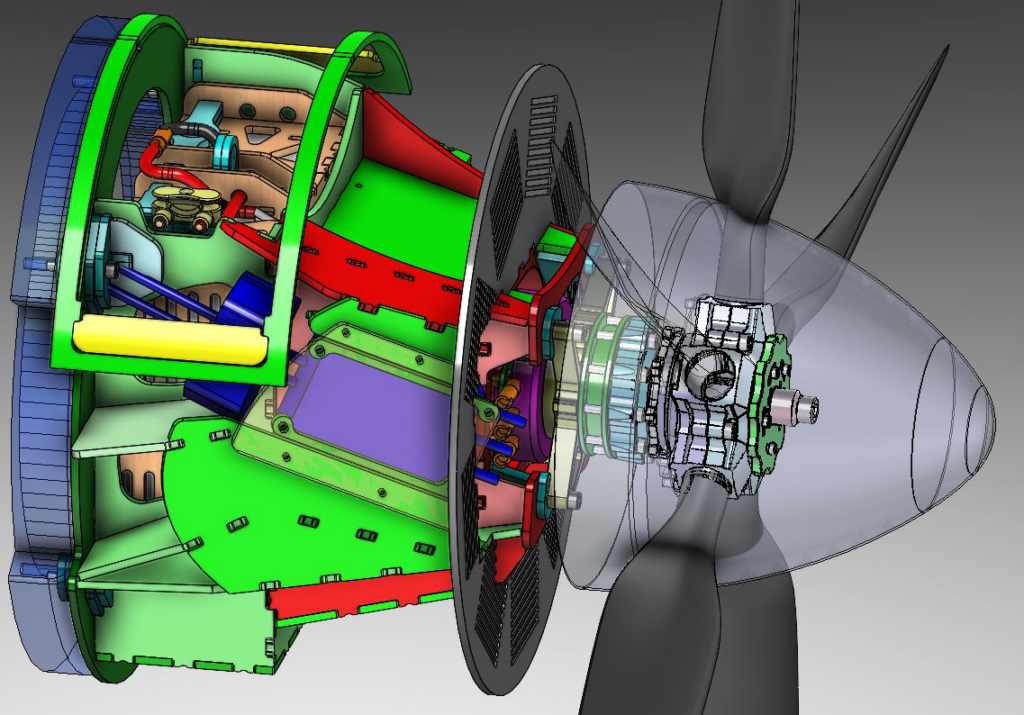

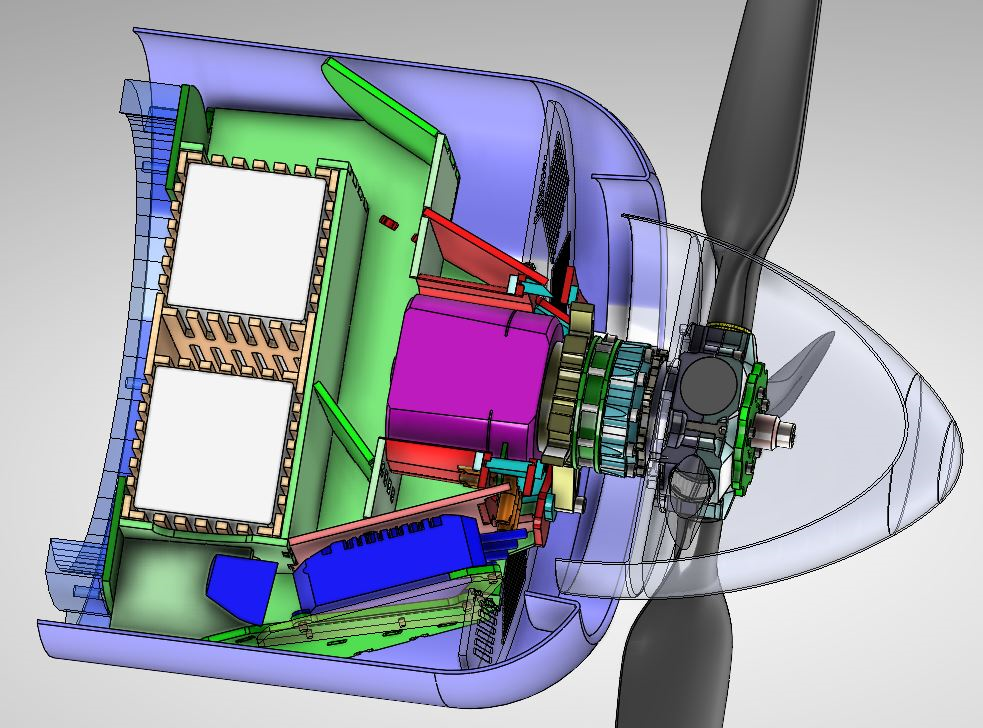

So it was obvious to strap our transmission, which had already been adapted to the Moki S250, in front of a corpulent electric motor. The design of the corresponding adapter parts for gearbox housing and sun gear was relatively unexciting. An external rotor engine with around 9kW rated power was flanged directly to the gearbox. An adapter part was integrated to mount the power plant on the airframe.

The components

After some calculating and recherge we chose the following components:

– our proved planetary gear drive with ratio 1:3

– a LMT 7040 Motor with nominal speed of 9000 rpm

– a 14S Lipo with 16.000 mAh

– a YGE-controller with max. current of 260A

The propeller speed range lays a little highter than the 2200 rpm the SP-250-X power plant was able to serve.

As a result, less steep pitch rates (around 40″ – 46″) are required and the E-SPX can now easily equip warbirds with 3-blade propellers such as the FW-190, which was rather difficult with the SP-250-X due to the high torque.

Another very positive effect of the extremely compact electric drive is, as already briefly mentioned above, that of course not only radially engine-powered warbirds can be equipped with it, but also all in-line engine aircraft types! Mustang, Spitfire, ME-109, to name only the most important, can be easily fired with this engine.

Even correspondingly high-diameter aerobatic planes such as SU-26 and others could be equipped very true to the original and, above all, with strong thrust.

All well and good, but

Drives are heavy, expensive, lame and above all have no sound!

Well, let’s take a closer look.

Heavy

The breakdown of the masses and costs has given a very surprising picture:

If you add up ALL the masses of the components of the SP-250-X 5-cylinder and compare this with those of the electric drive, it turns out that the electric drive has the same weight with a slightly lower flight time!

Radial engine, engine mount, ignition, battery, switch, gas and choke servo, tank, fuel, hoses…

will be exchanged by:

External rotor, battery, controller, motor mount, sound system

The gearbox weighs about the same as the SP-250-X, the propeller saves some gramms by more graceful blades.

All in all, we landed at the same weight and continue to fly our Seafury under 25kg!

Expensive

The costs of the above equipment are significantly lower with the electric drive! Even incl. charger! Admittedly, however, what still comes on top is a correspondingly large buffer battery, from which the flight battery is recharged on the airfield. In addition, a powerful power supply is advisable, to which the charger can be connected to charge the buffer battery at home.

However, if one calculates the fuel costs of the combustion variant against the battery wear costs + buffer battery and power supply, even these costs – depending on the annual number of flights – are quickly recovered. The cost of spare parts or wear for the star was not included here.

Lame

On the test bench, a maximum of 7kW / 12PS were determined for the Moki S250 under good cooling conditions with quite accurate computer-aided measurement technology despite tuning measures. As usual, the manufacturer’s technical data contains significantly more optimistic values.

Admittedly, if you feed the radial engine with around one liter of Stihl Motomix, you can fly full throttle for 15 minutes! There are pilots like that. But there are few mokis that master this gait for more than 20 flights.

In our electric Seafury we measured the following via the measuring technology, which is already supplied “for free” in the controller:

electricr power of motor: 9 kW

short time max. power consumption: 12 kW

Flight time: 9 min

with large-scale warbird flying style with some full-power loops and flythroughs and around 70% battery capacity utilization (11 Ah of 16 Ah nominal capacity)

We haven’t been in the air with Moki S250 warbirds at the same time, but we dare to say that in a loop with 200m height we can only get around slightly slower than we flew in below. We are curious to see which Moki comes with us.

Last but not least: The Sound!

Yes, the sound is missing! The electric drive with planetary gearbox and 3000 1/min fast rotating propeller has nothing in common with the original. Also missing is some of the low-frequency muffled roar of the 2000 1/min rotating propeller of the SP-250-X drive. Here you can hear more of a constant noise combined with a slightly singing sound comparable to that of a turbocharger.

But wait, there are sound modules!

And since a 25 kg plane is not a parking flyer, there is also no space and load capacity to produce correspondingly deep and loud engine noises. By the way, it should be mentioned that these are taken from the original and are therefore at least as authentic as the best model four-stroke!

Loudspeaker? No way! Transducers misuse the spacious fuselage and, if necessary, the wings as bass soundboxes and radiate sound properly!

Of course, it is not possible to generate several kilowatts of noise as with the combustion engine, but due to the abundant electrical power available directly from some of the drive batteries, impressive decibels can already be produced.

During the test run behind the house, you can be sure that even the next neighbor will raise his head when he enjoys a cultivated engine sound. And that should be enough in flight.

A fundamental point and, in our opinion, the most serious advantage of the electric drive has not yet been mentioned:

The Reliability

In contrast to the combustion engine, the drive unit is practically indifferent whether the humidity is higher today than yesterday, whether it is warm, cold or something else. Whether the valves are properly lubricated, whether cylinders or carburetors overheat, the plane is down, up, on the back, in a spin, the tank is half or completely full, all spark plugs spark cleanly and much more. The performance is simply on the stick, if you have not inserted a empty battery 😉

Of course, there can also be a spontaneous failure in the electric powertrain, which does not announce itself and forces the plane into the field from one second to the next.

Here, a lot depends on the original attention paid to the drive during design and installation. In particular, the cooling concept should be mentioned here.

There are also a few mechanical problem areas such as screws on propellers and lugs, plugs for power and control, fixation of the battery and the drive itself.

But – very big BUT:

The electric drive runs worlds less vibration, which helps the entire aircraft structure to a high degree to a massive increase in reliability: shaken linkages, all mechanical connections such as rudder hinges, push rods, cable hoists, the servos themselves and, last but not least, the complete installation of the electronic components including their internal vibration load.

And the speed of the electric drive is much better controlled: a stationary throttle that is too high or choppy cannot mess up the landing approach at the decisive moment. A dead stick in the landing curve does not demand the inevitable outer landing – just as a failure to overheat in the hot take-off phase does not result in a crash landing in the middle of nowhere.

Electric flying is for beginners

For people who are not men and can’t cope with a robust combustion engine! For suckers and wimps!

The electric pilot has only a mischievous smile on his face and waits calmly until Mr. Hardcore heads towards the cornfield to locate the remains of his machine, which must be scattered there somewhere. Just because one of those ball heads lost its ball. Something like that CAN’T be!!!

Precisely because planes of this size are not made of crumpled foam, a single crash, which is avoided by more reliability, is worth a few carats of gold!

Not to mention the risk for those present and the early construction season. We would like to say that there is no combustion plane pilot that does not know how to report something similar.

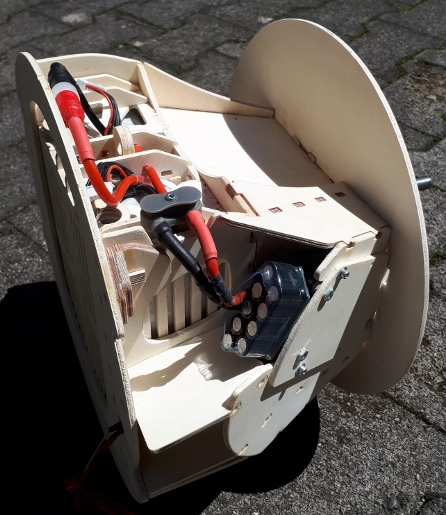

First of all, the installation concept

Since most of the weight of the combustion variant is in the 5-cylinder itself and this is suspended relatively far in front of the center of gravity, the tank must practically be in the center of gravity. This fits perfectly here, as the center of gravity remains constant regardless of the current amount of fuel.

The electric drive has the same weight overall, but the motor far forward is significantly lighter than the radial engine. This makes it possible to place the batteries and the controller also in front of the fire wall of the fuselage. The magic advantage is that no additional hull cutouts are needed to access and change the battery, but a simple lid in the cowling is sufficient, which does not weaken the hull structure.

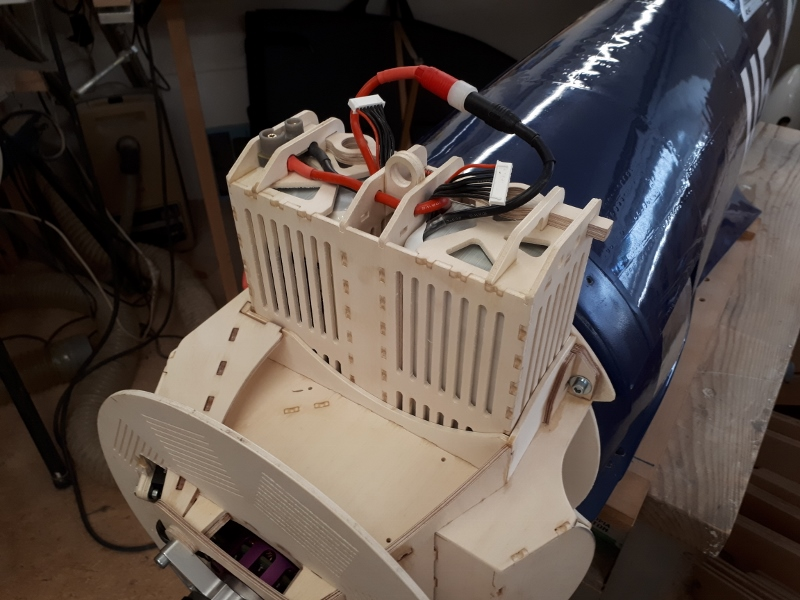

Thus, all components of the power plant can be integrated in the engine mount. With 5 screws, the unit is screwed directly to the fuselage frame by means of threat nuts.

Only the controller cable is plugged into the receiver and that’s it! This means that both in a new aircraft construction and conversion, the work on the airframe is extremely low in order to integrate the electric drive!

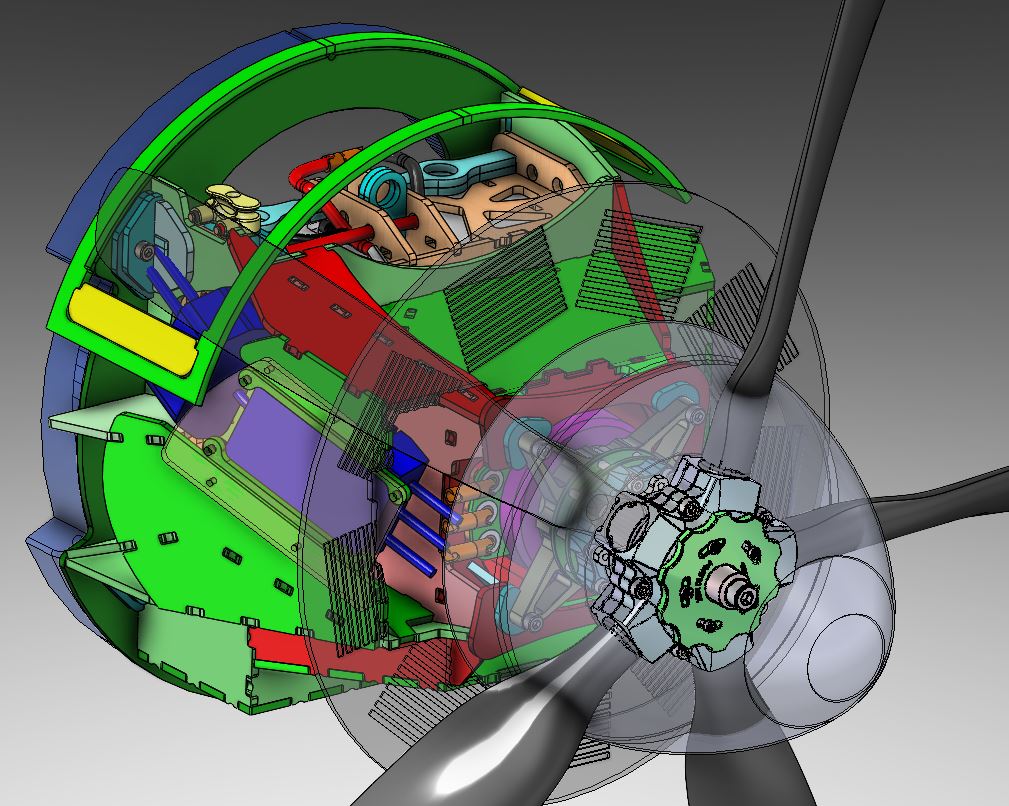

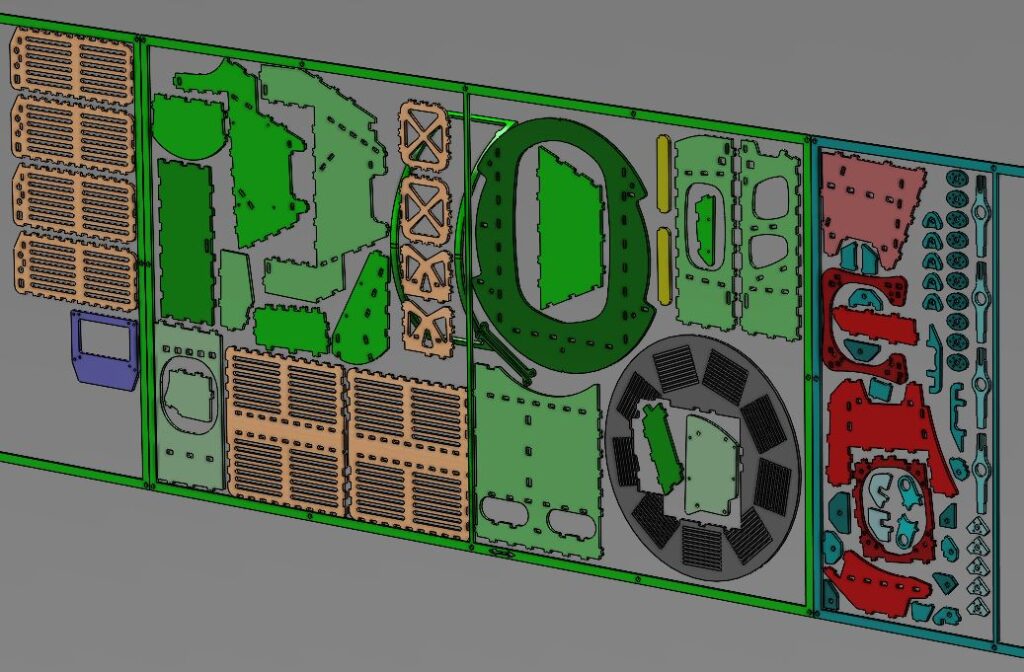

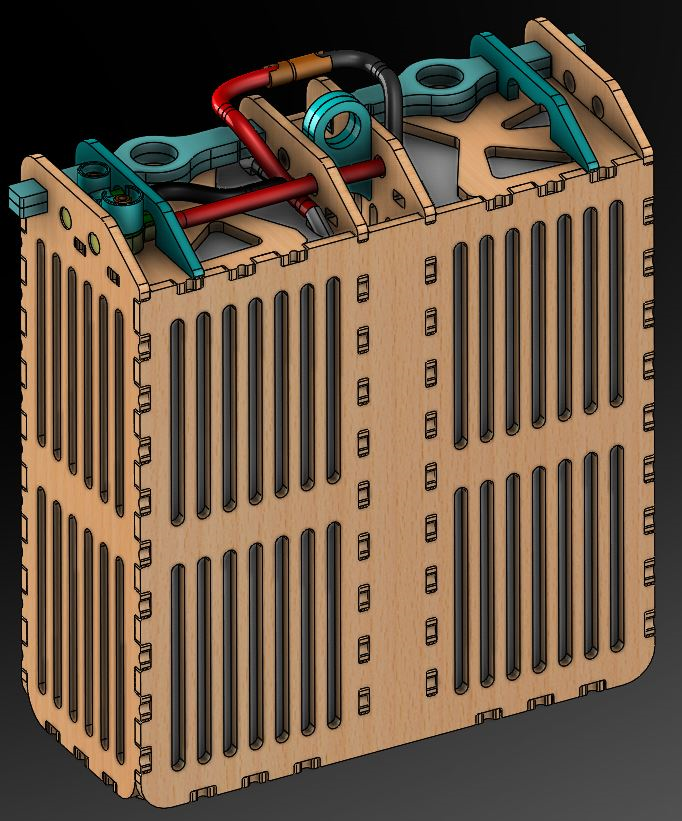

Design of motor mount kit

The complete structure in front of the fuselage head frame was created by CAD and designed in plywood plug-in construction. Highly loaded sections (red) were milled from 4mm aircraft plywood, the rest from light poplar plywood (green).

Needless to say, engine camber and side pull were provided and all components such as batteries, controller, gear drive and last but not least the sound module were drawn in several revisions. Everything was slipped and varied until it finally fit together perfectly.

From the very beginning, special emphasis was placed on the best possible cooling of all components. Despite quite good efficiencies, a significant waste heat is generated at 9 kW electrical power, which should not simply find its way somewhere uncoordinated.

In addition, the battery removal should be kept very simple and practical. The result is a 3D structure that meets all requirements.

The motor, battery pack and controller are each flowed separately with forcibly guided fresh cooling air and do not transfer their heat to the other components.

The air flowing in between spinner and cowling is dammed up by the front round bulkhead frame. This frame has milled the ribs of the 18-cylinder double star as a dummy from the front.

The motor itself is washed over, the controller is cooled separately from the side and the battery is blown through from bottom to top under the unit.

The exhaust air is blown off the sides in the area of the exhaust banks before the fuselage frame.

Even at high outside temperatures, the cooling of the system works perfectly.The battery pack sits in an air-permeable plywood box, which contains a bolt system at the top and thus keeps everything positive and securely locked in the battery bay. For loading and transport, the entire double block of 2x 7S 16,000 lipo is simply removed.

Of course, the main plug for the controller has been firmly integrated, so that its counterpart attached to the controller can be easily plugged in and removed.

The two 7-cell devices are connected via a connecting plug with lightning protection. This plug also serves to close the circuit and thus activates the drive. A removable insulation piece ensures that the individual plugs do not do stupid things when unplugged.

So much in advance. We would be delighted if this drive arouses your interest!

For more information, please contact us!